14 January 2008

Layout of standard cells for AMI 1.2

Overview

An extremely powerful concept in VLSI is the

standard cell library. Standard cells help create

efficient dense layouts because they are easily

abutted during the layout process. Standard cell

layout simply means that all standard cells - nand,

nor, not, etc. - in the design are layed out with

standard dimensions for heights, widths, actives and

wells, and have standard power (vdd!) and ground

(gnd!) busses.

The main purpose of this tutorial is to you how to

use Virtuoso Layout Editor and create a layout of an

inverter that could be used in a standard cell

library. The tutorial also includes instructions on

checking (DRC and LVS) the layout.

It is much easier to ensure that your standard cell

library is actually standard by creating a standard

cell template which you copy into your individual cell

layouts. All the standard cells in your library will

have a fixed height. We're going to set it at 90

lambda (54 microns: remember a 1.2 micron process has

a lambda of 0.6u). They will all have a minimum width,

but can be wider depending on the size of a cell. For

instance, inverters are very narrow, nand gates are

somewhat wider, and flip-flops are much wider. When

you need wider cells, simply abut multiple standard cell

templates together.

Fire up cadence (icfb) and create a library

following the instructions in Cadence Setup: For the first-time

user. In the Library Window, select the library

you have created and then select File -> New ->

Cellview... Make sure the Cell Name field reads

"template" and type "layout" in the View Name field.

After typing "layout", hit TAB and the Tool should

automatically change to Virtuoso. If it doesn't, then

manually change it by selecting the drop down box.

Select OK and the Virtuoso Layout Editing Window will

open, along with the Layer Select Window (LSW). The

LSW contains all of the different layers needed for

the layout process. (You will only need to use some

of these layers. Note: in the following picture, a

different technology library has been used, and thus

the layers are not quite the same as you will

see.)

The Virtuoso Layout Editing Tool has similar side

icons to those of the Virtuoso Schematic Editing Tool.

Some of the ones that will be used frequently in this

tutorial are the rectangle icon (or typing 'r') and

the ruler icon (or typing 'k'). The other icons are

pretty straight forward to understand and will be

referred to if they are needed.

The Virtuoso Layout Editing Tool has similar side

icons to those of the Virtuoso Schematic Editing Tool.

Some of the ones that will be used frequently in this

tutorial are the rectangle icon (or typing 'r') and

the ruler icon (or typing 'k'). The other icons are

pretty straight forward to understand and will be

referred to if they are needed.

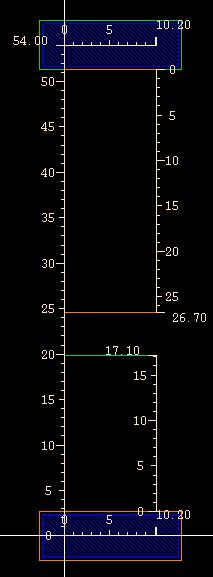

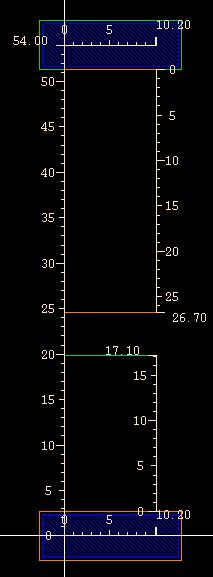

Use the ruler to measure out an area 54 u

tall and 10.2 u wide. Use the 0,0 origin as your

starting reference point. Your layout view should look

like the picture.

Make a power bus at the top of the cell. Use metal1

to draw a rectangle 4.8 u by 15 u. (The 'r' key

selects rectangle drawing.) Notice how it hangs over

the edges of the area we defined with the ruler? This

is so the cells adjoin easily later on. It should hang

2.4 u over the edge.

Copy the metal one rectangle and place the copy at

the bottom of the cell. This is your ground bus. Make

sure it also hangs over the cell area you defined the

same way the power bus does.

Because the vdd and gnd busses will be embedded in

nwells and pwells, we need to put nselect and pselect

around them. Put an nselect region around the vdd

bus. Make it 0.3 u larger on every side than the

metal1 rectangle. Put a similar pselect region around

the gnd bus.

Generally the pullup devices are larger than their

corresponding pulldown devices. Planning for this,

draw your n-select and p-select regions. Make the

pselect region take up about 2/3 of the cell. Draw a

pselect rectangle 26.7 u high by 10.2 u wide. Butt it

up against the nselect around the vdd bus. Draw an

nselect rectangle 17.1 u by 10.2 u. Butt it up against

the pselect around the gnd bus. Note, it will help you

to watch the delta X and delta Y coordinates at the

top of your screen while drawing rectangles.

Create the pwell and the nwell. The nwell goes

around the p-type transistors and the pwell goes

around the n-type transistors. The wells should extend

0.3 u around the p and n select boxes surrounding the

vdd and gnd busses. They should meet exactly between

the p and n select boxes in the body of the cell.

Create contacts to connect the vdd and gnd

busses. This helps avert latchup. To create contacts

press 'o' and select M1 to Active. Place three

contacts on the vdd bus and three on the gnd bus. Make

sure they are placed exactly at (0, 0), (5.1, 0),

(10.2, 0), (0, 54), (5.1, 54) and (10.2, 54).

In order to see what is inside the contacts, press

'e' to bring up the display options and set the display level

to 10. Display levels are referring to the layers on the chip layout but refer to levels of detail. What we are doing here is logically looking at details about our pins that relate back to the schematic.

Whenever you make edits to a layout, you need to

ensure that no layout design rules have been violated.

The tools help you with this by providing a "Design Rule Check" (DRC)

tool. To run DRC, save your layout and then select Verify -> DRC...

Make sure that the "Rules File" field contains

"divaDRC.rul". This is the file that contains all of

the design rules that the layout must adhere to. Make

sure that the "Rules Library" field contains "AMI12".

(NOTE: the picture below does not have the right

"Rules Library" field.) You do not need to worry about

changing any of the other options. Select OK. Then,

check the CIW to make sure there were no errors. If

there were any errors, the locations of errors will be

highlighted in the Virtuoso Layout Editing window (you

will see white lines, boxes, or crosses). Also, in

the CIW, it will tell you the design rules that have

been violated.

You can use the Verify -> Markers -> Find...

command from the menu to make it easier to find

violations. This command brings up a dialog box which

you can use to "step" through the violations,

highlighting or zooming into each one. Simply use the

"Next" and "Previous" button to move through the

violations.

Continue to edit the layout and fix violations until

there are no remaining violations.

Now lets use the standard cell template created in the

previous section to add an inverter to the standard

cell library.

Create a schematic for an inverter following

the instructions in Cell-level schematic

entry. Call the cell "inv".

Create a new cellview called "inv" but this time

choose layout for the cell type. Also open up the

standard cell template layout. Select the entire

template, press 'c' to open the copy dialog, click

somewhere in the template and them move the mouse over

to the inverter layout window. Place the template in

the inverter layout. Carefully place the lower left

contact right on the origin. Remember, in order for

the standard cells to abut correctly they need to

share a common origin.

Odds are the contacts do not look right. Press 'e' to open the display options and set Display Level Stop to 2.

Draw the inverter making sure it matches the pictures below and that the transistor widths are correct.

The inverter pullup: Draw a box of active 7.8 u by 10.8 u. Place a bar of poly 1.2 u wide. It should overlap the active by 1.2 u. Press 'o' to open the contacts menu. Select metal1 to active contacts, 1 column, 4 rows and place them as shown. Make a small rectangle of metal1 to connect the left side contacts to the vdd bus. Note: running DRC at this point is a good idea. It should pass easily. If it doesn't, make sure all the layers are sized correctly and try again.

The inverter pulldown: Draw a box of active 7.8 u

by 3.6 u. Stretch the bar of poly from the pullup

section down to the pulldown section. Make sure it

overlaps the active by 1.2 u. Press 'o' to open the

contacts menu. Select metal1 to active contact, 1

column, 1 rows and place two of them as shown. Make a

small rectangle of metal1 to connect the left side

contacts to the gnd bus. Note: The layout should pass

DRC at this point.

The contacts: Placing contacts in standard cells is

easy. The only things you need to think about are

routing lanes. You want to be able to route horizontal

tracks of metal 2 over your standard cells. Parallel

metal 2 paths must be separated by 2.4 u. That means

you can theoretically have a metal 2 path every 4.2 u

- that is, 2.4 u between paths and the paths are 1.8 u

wide. Our cells have routing tracks every 6 u. This

gives us a little extra room to manuver if we need

it.

Start on the x-axis and draw a ruler up the right

hand side of the inverter. See the figure below. Place

your output contact at 27 u or 21 u. Place your input

contact at 15 u. The input and output contacts are

metal 1 to metal 2 vias. In order to hook the input

contact up the the poly, place a metal 1 to poly

contact next to the poly, connect it with a small

piece of poly and then connect it to the input contact

with metal 1. The reason we didn't just stack this up

is that the process doesn't allow stacked vias. Most

newer processes do, this is just a quirk of the

technology we are working with.

Your contacts should look like the figure below.

Naming pins: Place two metal 2 layer shape pins and

two metal 2 layer shape pins. First, select metal 2 in

the LSW. (LSW stands for layer select window, it is

probably on the left side of the screen.) Go to Create

-> Pins and open the create pins window. Select

mode as shape pin and make sure rectangle is

selected. Select Display Name. In the terminal names

block, type A Y. Select I/O type as input. The create

pin box should look like the figure.

Go to the layout and draw a rectangle directly over

the metal 1 to metal 2 via on the input. Change I/O

type to output and do the same for the output via. You

should see something like the figure.

Now select metal 1 in the LSW. Create vdd and gnd

shape pins on top of the gnd and vdd busses. Set the

I/O type to inputoutput. Your finished inverter should

look like the figure.

Now save and run DRC. Fix any violations you find.

If you close the layout view and reopen it,

your pins may seem to disappear. They haven't; they've just

become invisible. Open the display options by pressing 'e'

and select "Pin Names" to make them visible again.

After you have completed a layout and it passes

DRC, it is extremely important that you check that the

layout you have created actually matches the schematic

for the cell. The tools provide a "Layout

vs. Schematic Check" (LVS) tool.

Before running, LVS, you must first "extract" the

layout. To do this, select Verify ->

Extract... in the Virtuoso Layout Editor window.

Leave all of the default settings and verify that

the "Rules File" is "divaEXT.rul" and the "Rules

Library" is "AMI12". Select OK. Verify that there are

no errors in the CIW. A new "extracted" cell view has

been created in your library. You can verify this by

checking in the Library Manager Window.

To run LVS, select

Verify -> LVS... in the Virtuoso Layout Editor

window. The LVS dialog window will appear. Enter the

library name and cell name in both the "schematic" and

"extracted" area of the dialog box. Set the "View" to

"schematic" and "extracted", respectively. (Note:

be careful to check this every time you run LVS,

particularly if you work on multiple cells.)

Ensure that the "Rules File" is "divaLVS.rul" and the

"Rules Library" is "AMI12". Make sure that all of the

other options read like the image below. (Note:

the image below has the wrong cell name and rules

library.)

To check that the layout and schematic are the

same, select Run. If the LVS succeeded, you should

get a message saying so. This may take a minute or

so to run.

This message means that LVS ran without crashing;

it does not necessarily mean that there weren't any

errors. In the LVS window, select Output to display

the results of the check. If there weren't any

errors, the output report should read "The netlists

match". If the netlists didn't match, it may be

because you used different names in the schematic from

the names you used in the layout. There are other

examples of why they won't match, but if you have

followed this tutorial and the previous one, you

shouldn't have any problems. (The output report can

also be found in a file "si.out" in a subdirectory

called "LVS" of the directory in which you invoked

icfb. In general, all sorts of run files which can

help debug LVS problems are in this subdirectory.)

The Virtuoso Layout Editing Tool has similar side

icons to those of the Virtuoso Schematic Editing Tool.

Some of the ones that will be used frequently in this

tutorial are the rectangle icon (or typing 'r') and

the ruler icon (or typing 'k'). The other icons are

pretty straight forward to understand and will be

referred to if they are needed.

The Virtuoso Layout Editing Tool has similar side

icons to those of the Virtuoso Schematic Editing Tool.

Some of the ones that will be used frequently in this

tutorial are the rectangle icon (or typing 'r') and

the ruler icon (or typing 'k'). The other icons are

pretty straight forward to understand and will be

referred to if they are needed.